Beddelka inta jeer ee inta badan wuxuu ka kooban yahay hagaajin (AC ilaa DC), filter, inverter (DC to AC), unit braking, unit drive, unit detection, micro processing unit, iwm. Intaa waxaa dheer, inverter-ku wuxuu leeyahay hawlo badan oo ilaalin ah, sida qulqulka xad-dhaafka ah, korantada xad-dhaafka ah, ilaalinta culeyska, iwm.

1. Badbaadinta tamarta soo noqnoqda

2. Kaydinta tamarta magdhowga factor - sababtoo ah doorka capacitor filter gudaha ee beddelka, lumitaanka tamarta falcelinta waa la dhimay iyo awoodda firfircoon ee shabakada ayaa kordhay

3. Badbaadinta tamarta bilawga jilicsan - iyadoo la adeegsanayo shaqada bilawga jilicsan ee beddelaha soo noqnoqda waxay ka dhigi doontaa bilawga bilawga ah ee eber, qiimaha ugu sarreeyana kama badan doono hadda la qiimeeyay, hoos u dhigista saameynta shabakada korantada iyo shuruudaha awoodda sahayda korontada, iyo kordhinta nolosha adeegga qalabka iyo valves. Qiimaha dayactirka qalabka waa la badbaadiyay.

2.1 Qoyaanka: qoyaanka qaraabada ahi waa in aanu dhaafin 50% heerkulka ugu badan ee 40°C, qoyaanka sare waxa lagu aqbali karaa heerkul hoose. Uumiga waa in si taxadar leh loo sameeyaa taas oo ay sababtay isbeddelka heerkulka.

Marka heerkulku ka sarreeyo + 40 ° C, goobta waa in si fiican loo hawo. Marka deegaanku yahay mid aan caadi ahayn, fadlan isticmaal kontoroolka telefishinka ama kabadhada korantada. Nolosha shaqada beddelka ayaa saamaysay goobta rakibidda. Isticmaalka muddada dheer ee joogtada ah, korantada korantada nolosha ee inverter kama badnaan doonto 5 sano, nolosha qaboojinta ma dhaafi doonto 3 sano, beddelka iyo dayactirka waa in la sameeyaa goor hore.

1.Frequency beddelashada tamarta badbaadinta

Badbaadinta tamarta beddelka soo noqnoqda inta badan waxa lagu muujiyaa adeegsiga marawaxada iyo bamka biyaha. Ka dib markii xeerbeegtida xawaaraha isbedbedelka ah loo ansixiyay culeyska marawaxadaha iyo bamka, heerka badbaadinta korantadu waa 20% ~ 60%, sababtoo ah isticmaalka dhabta ah ee tamarta marawaxada iyo culeyska bamka ayaa asal ahaan u dhigma awooda saddexaad ee xawaaraha. Marka celceliska socodka ay u baahan yihiin isticmaalayaashu uu yar yahay, taageerayaasha iyo bambooyinku waxay qaataan nidaamka xawaaraha beddelka ee soo noqnoqda si loo yareeyo xawaarahooda, iyo saamaynta kaydinta tamarta waa mid aad u muuqata. Halka taageereyaasha dhaqameed iyo bambooyinku ay u isticmaalaan dabaylo iyo mashiinnada xakamaynta socodka, xawaaraha matoorku asal ahaan isma beddelo, isticmaalka korontaduna wax yar ayuu isbeddelaa. Marka loo eego tirakoobyada, isticmaalka korantada marawaxada iyo matoorada bamka ayaa 31% ka ah isticmaalka tamarta qaranka iyo 50% isticmaalka tamarta warshadaha. Aad bay muhiim u tahay in la isticmaalo qalabka xakamaynta xawaaraha beddelka ee inta jeer ee culeyska noocaas ah. Waqtigan xaadirka ah, codsiyada guusha badan leh waxaa ka mid ah sahayda biyaha cadaadiska joogtada ah, nidaaminta xawaaraha soo noqnoqda ee kala duwan ee marawaxadaha kala duwan, qaboojiyaha dhexe iyo matoorada hawo-biyoodka.

2.Frequency beddelashada tamarta badbaadinta

Badbaadinta tamarta beddelka soo noqnoqda inta badan waxa lagu muujiyaa adeegsiga marawaxada iyo bamka biyaha. Ka dib markii xeerbeegtida xawaaraha isbedbedelka ah loo ansixiyay culeyska marawaxadaha iyo bamka, heerka badbaadinta korantadu waa 20% ~ 60%, sababtoo ah isticmaalka dhabta ah ee tamarta marawaxada iyo culeyska bamka ayaa asal ahaan u dhigma awooda saddexaad ee xawaaraha. Marka celceliska socodka ay u baahan yihiin isticmaalayaashu uu yar yahay, taageerayaasha iyo bambooyinku waxay qaataan nidaamka xawaaraha beddelka ee soo noqnoqda si loo yareeyo xawaarahooda, iyo saamaynta kaydinta tamarta waa mid aad u muuqata. Halka taageereyaasha dhaqameed iyo bambooyinku ay u isticmaalaan dabaylo iyo mashiinnada xakamaynta socodka, xawaaraha matoorku asal ahaan isma beddelo, isticmaalka korontaduna wax yar ayuu isbeddelaa. Marka loo eego tirakoobyada, isticmaalka korantada marawaxada iyo matoorada bamka ayaa 31% ka ah isticmaalka tamarta qaranka iyo 50% isticmaalka tamarta warshadaha. Aad bay muhiim u tahay in la isticmaalo qalabka xakamaynta xawaaraha beddelka ee inta jeer ee culeyska noocaas ah. Waqtigan xaadirka ah, codsiyada guusha badan leh waxaa ka mid ah sahayda biyaha cadaadiska joogtada ah, nidaaminta xawaaraha soo noqnoqda ee kala duwan ee marawaxadaha kala duwan, qaboojiyaha dhexe iyo matoorada hawo-biyoodka.

3.Codsiga hagaajinta heerka habka iyo tayada alaabta

Beddelaha soo noqnoqda ayaa sidoo kale si weyn loogu isticmaali karaa meelo kala duwan oo lagu xakameynayo qalabka farsamada sida gudbinta, qaadista, extrusion iyo qalabka mashiinka. Waxay hagaajin kartaa heerka habka iyo tayada badeecada, yareyn kartaa saameynta iyo sawaxanka qalabka, waxayna kordhin kartaa nolosha adeegga qalabka. Ka dib marka la qaato xakamaynta xakamaynta xawaaraha beddelka ee soo noqnoqda, nidaamka farsamada waa la fududeeyay, hawlgalka iyo xakamaynta ayaa ku habboon. Qaar ka mid ah xitaa waxay bedeli karaan qeexida habka asalka ah, sidaas darteed hagaajinta shaqada qalabka oo dhan. Tusaale ahaan, mashiinnada dharka iyo cabbirka ee loo isticmaalo warshado badan, heerkulka mashiinka dhexdiisa waxaa lagu hagaajiyaa iyadoo la beddelayo qadarka hawada kulul. Marwaxada wareegaysa waxaa badanaa loo isticmaalaa gudbinta hawo kulul. Maadaama xawaaraha marawaxadu uu yahay mid joogto ah, cadadka hawada kulul ee la quudiyo waxa kaliya oo hagaajin kara qoyaanka. Haddii dambarku uu ku guuldareysto inuu hagaajiyo ama si khaldan loo hagaajiyo, mashiinka wax lagu dhejiyo ayaa lumin doona xakamaynta, sidaas darteed saameynaya tayada alaabta la dhammeeyey. Marwaxada wareegaysa waxa ay ku bilaabataa xawli aad u sareeya, xidhashada u dhaxaysa suunka wadista iyo xajinta ayaa ah mid aad u daran, taas oo ka dhigaysa suunka wadista mid la isticmaali karo. Ka dib marka la ansixiyo nidaamka xawaaraha beddelka soo noqnoqda, nidaaminta heerkulka waxaa lagu xaqiijin karaa beddelaha soo noqnoqda si uu si toos ah u hagaajiyo xawaaraha marawaxada, kaas oo xalliya dhibaatada tayada alaabta. Intaa waxaa dheer, beddelaha soo noqnoqda wuxuu si fudud u bilaabi karaa marawaxada xawaare hooseeya iyo xawaare hooseeya, wuxuu yareeyaa xidhashada u dhaxaysa suunka darawalnimada iyo xajinta, wuxuu kordhiyaa nolosha adeegga qalabka, wuxuuna kaydiyaa tamarta 40%.

4.Realization of motor jilicsan bilowga

Ku bilawga adag ee matoorku kaliya kuma keenayo saamayn ba'an shabkada korantada, laakiin waxa kale oo ay u baahan tahay awood badan oo koronto ah. Hadda iyo gariirka weyn ee dhasha inta lagu jiro bilowga waxay dhaawac weyn u geysan doonaan gariirada iyo mashiinnada, waxayna si aad ah u dhaawaceysaa nolosha adeegga qalabka iyo dhuumaha. Ka dib markii la isticmaalo inverter ah, shaqada bilowga jilicsan ee inverter ka dhigi doonaa bilowga ah isbeddelka hadda ka eber, iyo qiimaha ugu badan ma dhaafi doono hadda la qiimeeyay, hoos u dhigi doonaa saamaynta on shabakada korontada iyo shuruudaha awoodda sahayda korontada, kordhinta nolosha adeegga qalabka iyo valves, iyo sidoo kale badbaadinta kharashka dayactirka qalabka.

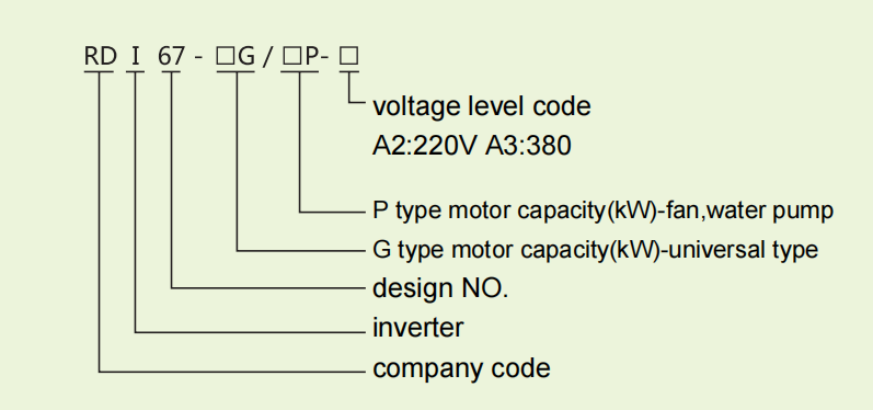

Tilmaamid

Nooca korantada: 380V iyo 220V

Awoodda Baabuurka: 0.75kW ilaa 315kW

Faahfaahinta eeg Shaxda1

| Voltage | Qaabka No. | Awoodda la qiimeeyay (kVA) | Wax soo saarka hadda la qiimeeyay (A) | Matoorka codsanaya (kW) |

| 380V saddex waji | RDI67-0.75G-A3 | 1.5 | 2.3 | 0.75 |

| RDI67-1.5G-A3 | 3.7 | 3.7 | 1.5 | |

| RDI67-2.2G-A3 | 4.7 | 5.0 | 2.2 | |

| RDI67-4G-A3 | 6.1 | 8.5 | 4.0 | |

| RDI67-5.5G/7.5P-A3 | 11 | 13 | 5.5 | |

| RDI67-7.5G/11P-A3 | 14 | 17 | 7.5 | |

| RDI67-11G/15P-A3 | 21 | 25 | 11 | |

| RDI67-15G/18.5P-A3 | 26 | 33 | 15 | |

| RDI67-18.5G/22P-A3 | 31 | 39 | 18.5 | |

| RDI67-22G/30P-A3 | 37 | 45 | 22 | |

| RDI67-30G/37P-A3 | 50 | 60 | 30 | |

| RDI67-37G/45P-A3 | 61 | 75 | 37 | |

| RDI67-45G/55P-A3 | 73 | 90 | 45 | |

| RDI67-55G/75P-A3 | 98 | 110 | 55 | |

| RDI67-75G/90P-A3 | 130 | 150 | 75 | |

| RDI67-93G/110P-A3 | 170 | 176 | 90 | |

| RDI67-110G/132P-A3 | 138 | 210 | 110 | |

| RDI67-132G/160P-A3 | 167 | 250 | 132 | |

| RDI67-160G/185P-A3 | 230 | 310 | 160 | |

| RDI67-200G/220P-A3 | 250 | 380 | 200 | |

| RDI67-220G-A3 | 258 | 415 | 220 | |

| RDI67-250G-A3 | 340 | 475 | 245 | |

| RDI67-280G-A3 | 450 | 510 | 280 | |

| RDI67-315G-A3 | 460 | 605 | 315 | |

| 220V hal waji | RDI67-0.75G-A3 | 1.4 | 4.0 | 0.75 |

| RDI67-1.5G-A3 | 2.6 | 7.0 | 1.2 | |

| RDI67-2.2G-A3 | 3.8 | 10.0 | 2.2 |

Hal waji oo taxane ah 220V

| Matoorka codsanaya (kW) | Qaabka No. | Jaantuska | Cabirka: (mm) | |||||

| 220 taxane | A | B | C | G | H | intall bool | ||

| 0.75 ~ 2.2 | 0.75 kW ~ 2.2kW | Jaantuska2 | 125 | 171 | 165 | 112 | 160 | M4 |

Saddex weji oo taxane ah 380V

| Matoorka codsanaya (kW) | Qaabka No. | Jaantuska | Cabirka: (mm) | |||||

| 220 taxane | A | B | C | G | H | intall bool | ||

| 0.75 ~ 2.2 | 0.75kW~2.2kW | Jaantuska2 | 125 | 171 | 165 | 112 | 160 | M4 |

| 4 | 4kW | 150 | 220 | 175 | 138 | 208 | M5 | |

| 5.5 ~ 7.5 | 5.5kW ~ 7.5kW | 217 | 300 | 215 | 205 | 288 | M6 | |

| 11 | 11kW | Jaantuska3 | 230 | 370 | 215 | 140 | 360 | M8 |

| 15 ~ 22 | 15kW~22kW | 255 | 440 | 240 | 200 | 420 | M10 | |

| 30 ~ 37 | 30kW ~ 37kW | 315 | 570 | 260 | 230 | 550 | ||

| 45 ~ 55 | 45kW ~ 55kW | 320 | 580 | 310 | 240 | 555 | ||

| 75 ~ 93 | 75kW~93kW | 430 | 685 | 365 | 260 | 655 | ||

| 110 ~ 132 | 110kW ~ 132kW | 490 | 810 | 360 | 325 | 785 | ||

| 160-200 | 160kW ~ 200kW | 600 | 900 | 355 | 435 | 870 | ||

| 220 | 200kW ~ 250kW | Jaantuska4 | 710 | 1700 | 410 | Ku rakibida golaha wasiirada | ||

| 250 | ||||||||

| 280 | 280kW ~ 400kW | 800 | 1900kii | 420 | ||||

| 315 | ||||||||

Muuqashada iyo cabbirka kor u kaca

Cabbirka qaabka eeg sawirka2, Fig3, Fig4, qaabka kiiska hawlgalka eeg sawirka1

1.Frequency beddelashada tamarta badbaadinta

Badbaadinta tamarta beddelka soo noqnoqda inta badan waxa lagu muujiyaa adeegsiga marawaxada iyo bamka biyaha. Ka dib markii xeerbeegtida xawaaraha isbedbedelka ah loo ansixiyay culeyska marawaxadaha iyo bamka, heerka badbaadinta korantadu waa 20% ~ 60%, sababtoo ah isticmaalka dhabta ah ee tamarta marawaxada iyo culeyska bamka ayaa asal ahaan u dhigma awooda saddexaad ee xawaaraha. Marka celceliska socodka ay u baahan yihiin isticmaalayaashu uu yar yahay, taageerayaasha iyo bambooyinku waxay qaataan nidaamka xawaaraha beddelka ee soo noqnoqda si loo yareeyo xawaarahooda, iyo saamaynta kaydinta tamarta waa mid aad u muuqata. Halka taageereyaasha dhaqameed iyo bambooyinku ay u isticmaalaan dabaylo iyo mashiinnada xakamaynta socodka, xawaaraha matoorku asal ahaan isma beddelo, isticmaalka korontaduna wax yar ayuu isbeddelaa. Marka loo eego tirakoobyada, isticmaalka korantada marawaxada iyo matoorada bamka ayaa 31% ka ah isticmaalka tamarta qaranka iyo 50% isticmaalka tamarta warshadaha. Aad bay muhiim u tahay in la isticmaalo qalabka xakamaynta xawaaraha beddelka ee inta jeer ee culeyska noocaas ah. Waqtigan xaadirka ah, codsiyada guusha badan leh waxaa ka mid ah sahayda biyaha cadaadiska joogtada ah, nidaaminta xawaaraha soo noqnoqda ee kala duwan ee marawaxadaha kala duwan, qaboojiyaha dhexe iyo matoorada hawo-biyoodka.

2.Frequency beddelashada tamarta badbaadinta

Badbaadinta tamarta beddelka soo noqnoqda inta badan waxa lagu muujiyaa adeegsiga marawaxada iyo bamka biyaha. Ka dib markii xeerbeegtida xawaaraha isbedbedelka ah loo ansixiyay culeyska marawaxadaha iyo bamka, heerka badbaadinta korantadu waa 20% ~ 60%, sababtoo ah isticmaalka dhabta ah ee tamarta marawaxada iyo culeyska bamka ayaa asal ahaan u dhigma awooda saddexaad ee xawaaraha. Marka celceliska socodka ay u baahan yihiin isticmaalayaashu uu yar yahay, taageerayaasha iyo bambooyinku waxay qaataan nidaamka xawaaraha beddelka ee soo noqnoqda si loo yareeyo xawaarahooda, iyo saamaynta kaydinta tamarta waa mid aad u muuqata. Halka taageereyaasha dhaqameed iyo bambooyinku ay u isticmaalaan dabaylo iyo mashiinnada xakamaynta socodka, xawaaraha matoorku asal ahaan isma beddelo, isticmaalka korontaduna wax yar ayuu isbeddelaa. Marka loo eego tirakoobyada, isticmaalka korantada marawaxada iyo matoorada bamka ayaa 31% ka ah isticmaalka tamarta qaranka iyo 50% isticmaalka tamarta warshadaha. Aad bay muhiim u tahay in la isticmaalo qalabka xakamaynta xawaaraha beddelka ee inta jeer ee culeyska noocaas ah. Waqtigan xaadirka ah, codsiyada guusha badan leh waxaa ka mid ah sahayda biyaha cadaadiska joogtada ah, nidaaminta xawaaraha soo noqnoqda ee kala duwan ee marawaxadaha kala duwan, qaboojiyaha dhexe iyo matoorada hawo-biyoodka.

3.Codsiga hagaajinta heerka habka iyo tayada alaabta

Beddelaha soo noqnoqda ayaa sidoo kale si weyn loogu isticmaali karaa meelo kala duwan oo lagu xakameynayo qalabka farsamada sida gudbinta, qaadista, extrusion iyo qalabka mashiinka. Waxay hagaajin kartaa heerka habka iyo tayada badeecada, yareyn kartaa saameynta iyo sawaxanka qalabka, waxayna kordhin kartaa nolosha adeegga qalabka. Ka dib marka la qaato xakamaynta xakamaynta xawaaraha beddelka ee soo noqnoqda, nidaamka farsamada waa la fududeeyay, hawlgalka iyo xakamaynta ayaa ku habboon. Qaar ka mid ah xitaa waxay bedeli karaan qeexida habka asalka ah, sidaas darteed hagaajinta shaqada qalabka oo dhan. Tusaale ahaan, mashiinnada dharka iyo cabbirka ee loo isticmaalo warshado badan, heerkulka mashiinka dhexdiisa waxaa lagu hagaajiyaa iyadoo la beddelayo qadarka hawada kulul. Marwaxada wareegaysa waxaa badanaa loo isticmaalaa gudbinta hawo kulul. Maadaama xawaaraha marawaxadu uu yahay mid joogto ah, cadadka hawada kulul ee la quudiyo waxa kaliya oo hagaajin kara qoyaanka. Haddii dambarku uu ku guuldareysto inuu hagaajiyo ama si khaldan loo hagaajiyo, mashiinka wax lagu dhejiyo ayaa lumin doona xakamaynta, sidaas darteed saameynaya tayada alaabta la dhammeeyey. Marwaxada wareegaysa waxa ay ku bilaabataa xawli aad u sareeya, xidhashada u dhaxaysa suunka wadista iyo xajinta ayaa ah mid aad u daran, taas oo ka dhigaysa suunka wadista mid la isticmaali karo. Ka dib marka la ansixiyo nidaamka xawaaraha beddelka soo noqnoqda, nidaaminta heerkulka waxaa lagu xaqiijin karaa beddelaha soo noqnoqda si uu si toos ah u hagaajiyo xawaaraha marawaxada, kaas oo xalliya dhibaatada tayada alaabta. Intaa waxaa dheer, beddelaha soo noqnoqda wuxuu si fudud u bilaabi karaa marawaxada xawaare hooseeya iyo xawaare hooseeya, wuxuu yareeyaa xidhashada u dhaxaysa suunka darawalnimada iyo xajinta, wuxuu kordhiyaa nolosha adeegga qalabka, wuxuuna kaydiyaa tamarta 40%.

4.Realization of motor jilicsan bilowga

Ku bilawga adag ee matoorku kaliya kuma keenayo saamayn ba'an shabkada korantada, laakiin waxa kale oo ay u baahan tahay awood badan oo koronto ah. Hadda iyo gariirka weyn ee dhasha inta lagu jiro bilowga waxay dhaawac weyn u geysan doonaan gariirada iyo mashiinnada, waxayna si aad ah u dhaawaceysaa nolosha adeegga qalabka iyo dhuumaha. Ka dib markii la isticmaalo inverter ah, shaqada bilowga jilicsan ee inverter ka dhigi doonaa bilowga ah isbeddelka hadda ka eber, iyo qiimaha ugu badan ma dhaafi doono hadda la qiimeeyay, hoos u dhigi doonaa saamaynta on shabakada korontada iyo shuruudaha awoodda sahayda korontada, kordhinta nolosha adeegga qalabka iyo valves, iyo sidoo kale badbaadinta kharashka dayactirka qalabka.

Tilmaamid

Nooca korantada: 380V iyo 220V

Awoodda Baabuurka: 0.75kW ilaa 315kW

Faahfaahinta eeg Shaxda1

| Voltage | Qaabka No. | Awoodda la qiimeeyay (kVA) | Wax soo saarka hadda la qiimeeyay (A) | Matoorka codsanaya (kW) |

| 380V saddex waji | RDI67-0.75G-A3 | 1.5 | 2.3 | 0.75 |

| RDI67-1.5G-A3 | 3.7 | 3.7 | 1.5 | |

| RDI67-2.2G-A3 | 4.7 | 5.0 | 2.2 | |

| RDI67-4G-A3 | 6.1 | 8.5 | 4.0 | |

| RDI67-5.5G/7.5P-A3 | 11 | 13 | 5.5 | |

| RDI67-7.5G/11P-A3 | 14 | 17 | 7.5 | |

| RDI67-11G/15P-A3 | 21 | 25 | 11 | |

| RDI67-15G/18.5P-A3 | 26 | 33 | 15 | |

| RDI67-18.5G/22P-A3 | 31 | 39 | 18.5 | |

| RDI67-22G/30P-A3 | 37 | 45 | 22 | |

| RDI67-30G/37P-A3 | 50 | 60 | 30 | |

| RDI67-37G/45P-A3 | 61 | 75 | 37 | |

| RDI67-45G/55P-A3 | 73 | 90 | 45 | |

| RDI67-55G/75P-A3 | 98 | 110 | 55 | |

| RDI67-75G/90P-A3 | 130 | 150 | 75 | |

| RDI67-93G/110P-A3 | 170 | 176 | 90 | |

| RDI67-110G/132P-A3 | 138 | 210 | 110 | |

| RDI67-132G/160P-A3 | 167 | 250 | 132 | |

| RDI67-160G/185P-A3 | 230 | 310 | 160 | |

| RDI67-200G/220P-A3 | 250 | 380 | 200 | |

| RDI67-220G-A3 | 258 | 415 | 220 | |

| RDI67-250G-A3 | 340 | 475 | 245 | |

| RDI67-280G-A3 | 450 | 510 | 280 | |

| RDI67-315G-A3 | 460 | 605 | 315 | |

| 220V hal waji | RDI67-0.75G-A3 | 1.4 | 4.0 | 0.75 |

| RDI67-1.5G-A3 | 2.6 | 7.0 | 1.2 | |

| RDI67-2.2G-A3 | 3.8 | 10.0 | 2.2 |

Hal waji oo taxane ah 220V

| Matoorka codsanaya (kW) | Qaabka No. | Jaantuska | Cabirka: (mm) | |||||

| 220 taxane | A | B | C | G | H | intall bool | ||

| 0.75 ~ 2.2 | 0.75 kW ~ 2.2kW | Jaantuska2 | 125 | 171 | 165 | 112 | 160 | M4 |

Saddex weji oo taxane ah 380V

| Matoorka codsanaya (kW) | Qaabka No. | Jaantuska | Cabirka: (mm) | |||||

| 220 taxane | A | B | C | G | H | intall bool | ||

| 0.75 ~ 2.2 | 0.75kW~2.2kW | Jaantuska2 | 125 | 171 | 165 | 112 | 160 | M4 |

| 4 | 4kW | 150 | 220 | 175 | 138 | 208 | M5 | |

| 5.5 ~ 7.5 | 5.5kW ~ 7.5kW | 217 | 300 | 215 | 205 | 288 | M6 | |

| 11 | 11kW | Jaantuska3 | 230 | 370 | 215 | 140 | 360 | M8 |

| 15 ~ 22 | 15kW~22kW | 255 | 440 | 240 | 200 | 420 | M10 | |

| 30 ~ 37 | 30kW ~ 37kW | 315 | 570 | 260 | 230 | 550 | ||

| 45 ~ 55 | 45kW ~ 55kW | 320 | 580 | 310 | 240 | 555 | ||

| 75 ~ 93 | 75kW~93kW | 430 | 685 | 365 | 260 | 655 | ||

| 110 ~ 132 | 110kW ~ 132kW | 490 | 810 | 360 | 325 | 785 | ||

| 160-200 | 160kW ~ 200kW | 600 | 900 | 355 | 435 | 870 | ||

| 220 | 200kW ~ 250kW | Jaantuska4 | 710 | 1700 | 410 | Ku rakibida golaha wasiirada | ||

| 250 | ||||||||

| 280 | 280kW ~ 400kW | 800 | 1900kii | 420 | ||||

| 315 | ||||||||

Muuqashada iyo cabbirka kor u kaca

Cabbirka qaabka eeg sawirka2, Fig3, Fig4, qaabka kiiska hawlgalka eeg sawirka1